Boeing Poised To Begin 777X Assembly

Incredibly, it was almost a quarter of a century ago that Boeing program managers described the impending convergence of parts for construction of the first 777 at Everett, Washington, as an “aluminum avalanche.” Fast forward to 2018...

Feb 26, 2018 | Aviation Week

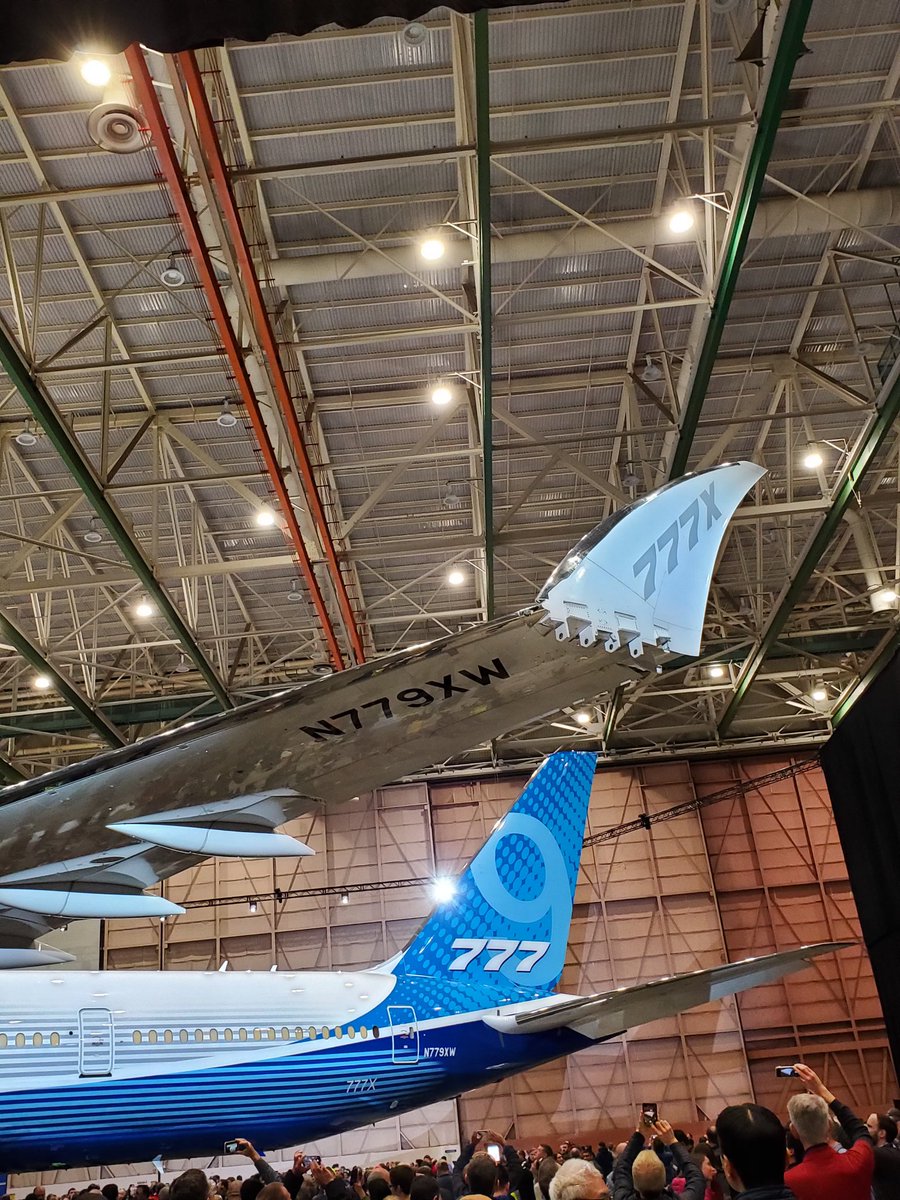

Incredibly, it was almost a quarter of a century ago that Boeing program managers described the impending convergence of parts for construction of the first 777 at Everett, Washington, as an “aluminum avalanche.” Fast forward to 2018 and, while the avalanche contains a far larger proportion of composite materials this time, the scene is being repeated as Boeing prepares to assemble the first new-generation 777-9.

From the official launch of the 777X in 2013 to the building of the cavernous $1 billion Composite Wing Center (CWC), where the skin and bones of Boeing’s first in-house, large-scale nonmetallic wings are formed, the process of crafting the company’s new high-capacity flagship culminates with final assembly later this year. “As far as I am concerned, the engineering is released to go build the airplane,” says 777X chief project engineer Michael Teal. “We are somewhere in the 93-95% design release region now, but the reality is that it is all released.”

Initial fuselage panels for first 777-9 are en route from Japan to Everett, Washington. Boeing learns lessons from “difficult” first composite wing assembly First integrated systems tests are beginning in Seattle-area labs “The engineering needs to be done right now because we are actually building the airplane,” adds 777X Vice President and General Manager Eric Lindblad. Design release for structures “is done, though for systems we have more work to do, as we also do for some of the propulsion-engine build-up installation,” he notes. “The interiors will follow because we are configuring the interior of the aircraft, and that work is further back, but the bulk of the hard parts on the airplane are done.”

Assembly of the first production wing spar for the first flight-test 777-9 began in October, and spar fabrication for the second and third flight-test aircraft is also underway in the CWC. In all six 777-9 airframes, four of them for flight testing and one each for static and fatigue tests, will be assembled this year. Rollout of the first 777-9X is due at the end of the year, with the first flight provisionally expected around February 2019.

Boeing cut its teeth on the preliminary phases of the 777X wing program by producing a prototype wingbox from spars, stringers and skin panels made in the CWC. Assembly takes place on a newly established horizontal build line (HBL). “That’s where we take the spars, add the ribs and put the upper panel on before we drill it, fill it and then move it to do the same for the lower panel,” Teal says. “We have completed the whole process for the prototype, so now the next pair of wings coming through are for the static-test aircraft. They are in their final phases. The upper panel is done and fixed, and the lower panel is being done right now.

“Fundamentally, the first airplane is going to be built soon. The wings are just about to be completed and will leave the HBL,” Teal says. Unlike the follow-on wing sets for the flight-test aircraft, the units for the static airframe will not pass to the wing laydown line for “stuffing” with ducts, pipes and wiring for flight control and other systems. “They are not required to have all that equipment because it is the static-test airframe,” Teal says. The components for the first flight-test aircraft airplane are also ready to go to the HBL. “It’s been through the spar line and the wing panels are there, so we are just waiting to get it scheduled to go through wing assembly, and we are pretty close to getting that done,” he adds.

Putting together the 105-ft.-long wingbox structures has not been easy, Lindblad acknowledges. “Initial wing assembly has been difficult. We were sharing this with the guys from [Mitsubishi Heavy Industries, the Japanese manufacturer responsible for building the composite wings for the 787], and I was telling them about the shimming we have to go through,” he says. “They have been great about helping us through their learnings. They gave us advice on how to speed up measuring the gaps as well as some ideas about how to turn the shims around. We talked about the best sequence, so it was more a logistics discussion rather than engineering.”

Boeing assembles the left-hand wings before working on the right. “Every single wing we build, we incorporate the learnings from the last, and we will get through it, but it has certainly been difficult for us,” Lindblad emphasizes. The main issues have centered on the details of the assembly process, such as determining the correct numbers and placement of the temporary fasteners that attach skin panels to the spars and ribs. “Fundamentally, we know it goes together; it’s just fine-tuning the process we have got,” Lindblad says. The first set of fuselage subassemblies are already en route to the U.S. from Japan. Mitsubishi Heavy Industries supplies panels for the aft fuselage section, Kawasaki Heavy Industries produces panels for the center and forward fuselage section and Subaru (formerly Fuji Heavy Industries) makes the 11/45 center wingbox. “They started shipping [Feb. 7] and will arrive here in Everett over the next few weeks. In March, we will start fuselage assembly work, and my assessment is the Japanese partners have done a phenomenal job,” Lindblad says. Assembly of the initial aircraft will take place at a temporary location in Building 40-23 between the current 747-8 and 777 assembly lines. Dubbed the low-rate, initial-production line, the site will be used to prove the production process on the new 777 variant without disrupting the adjacent 777-300ER. Final body join for the static airframe will occur in the second quarter, with the same milestone moment for the first flight-test aircraft set for the June-July time frame.

More than 30 ground-test labs, most of them in the Seattle area, are now up and running. The majority are component test benches for evaluating the hardware and software of each line-replaceable unit. “Right now, we are over 50% complete in terms of all the detailed test plans on those benches, and we will climb that curve,” Teal says. “Over the next month and a half or so, we will have wrung it all out.” For the next level, in which components such as hydraulics, actuators and flight controls are brought together for the first time, Boeing has set up the Integrated Test Vehicle. “That vehicle is up and running and executing today,” he says, adding that the facility is “halfway up the curve of what we need it to do.”

The E-Cab, an engineering fixed-base flight deck simulator, is also operational. “We declared it ready for test in January, and right now pilots are in it every day doing checkouts of flight control software and how it integrates with the avionics,” Teal notes. The final major test site, located at Boeing Field and dubbed Airplane Zero, incorporates all the laboratories and connects them with a simulation of the actual aircraft wiring. “It’s an airplane on the lab floor which we will turn on to make sure it works. We will be doing that in the second quarter of this year,” Teal explains. The big lab is in development to support assembly of the first flight-test aircraft for which “we will be turning on the power and getting it all running and humming by the middle of the third quarter or so,” he adds.

One watch item for the program, meanwhile, continues to be the delayed first flight of the 777X’s engine, the General Electric GE9X. Originally scheduled to begin evaluation at the start of the year on GE’s 747-400 flying testbed at Victorville, California, the test effort has been delayed by the discovery of a minor design issue with the variable stator vane (VSV) actuator arms of the new turbofan as well as maintenance-related problems with the testbed’s CF6 engines.

GE, which insists the slip will not jeopardize the schedule for the overall engine certification program or the first flight of the 777X, is still deciding whether or not to proceed with flight tests using the engine with the existing VSV configuration, or delay until the revised version is available. Although this decision was originally expected around mid-February, it had still not been made on Feb. 23. The issue is related to the discovery of exceedance loads on the lever arms that actuate the VSV rows in the 11-stage high-pressure compressor and was only revealed during runs on a demonstrator engine late last year. The GE9X slip marks the first major schedule challenge for the 777X, which to date has progressed smoothly and to plan since the Boeing board approved its launch in 2012. The successful development of the 105,000-lb.-rated GE9X, which is the exclusive engine for the stretched Boeing twinjet, is critical to the program and has itself remained on track up to this point.

The problem “has caused us to have to look at the schedule and start to run different scenarios about how to juggle things around so we can still accommodate the program schedule,” Lindblad says. “We think we have a way to do that, but we have to work hard to make it fit.” Although Boeing automatically builds some margin into the engine development schedule for its new models, each passing week without starting flight testing eats into this buffer. “I think we know how to absorb it and make the schedule impact a nonissue, but there is more work to do,” Teal says.

Despite Boeing’s confidence, the company is inevitably concerned. “I’d love to be further along and moving into some ice testing and ultimately to the rig test for fan blade-out, without having to make further hardware changes to the engine,” Lindblad admits. “I would have liked to have those behind me before we had to deal with it. I was told we are going to have a discovery on every new program, and I think we just had ours early.”

However, GE reports positive progress with other elements of the GE9X program. The third test engine is undergoing crosswind evaluations at the company’s Peebles facility in Ohio. The fifth engine in the series (designated Engine No. 007), has begun evaluation in the company’s icing test facility in Winnipeg, Manitoba. Engine Nos. 005, 006 and 008 are under assembly. The initial flight-test engines for the first 777X will be shipped to Boeing later in 2018.

- Roles

- Subject

- Media

- Event

Boeing Poised To Begin 777X Assembly

Feb 26, 2018 | Aviation Week

Incredibly, it was almost a quarter of a century ago that Boeing program managers described the impending convergence of parts for construction of the first 777 at Everett, Washington, as an “aluminum avalanche.” Fast forward to 2018...

VIDEO: World's Largest 3D Printed Object for 777X

Feb 9, 2018 | Innovations

Boeing partnered with the U.S. Department of Energy’s Oak Ridge National Laboratory (ORNL) to create a tool used to build the folding wing tip for the forthcoming 777X airplane. The wing trim and drill tool is ...

FACEBOOK LIVE: A Behind the Scenes Look at th...

Feb 8, 2018 | Boeing Commercial

Click to Watch the Facebook LIVE

VIDEO: 'Listening' to the new 777X window pan...

Oct 10, 2017 | Boeing Commercial

Click to Watch the Video

State of the art 777X Composite Wing Center completes parts

Dec 6, 2016 | Boeing Commercial

Construction on the 1.3 million-square-foot (121,000-square-meter) building continues, as it will for the next 18 months, with the roll-in of new tools and equipment.

Touchscreens come to 777X flight deck

Jul 1, 2016 | Boeing Commercial

Boeing's innovation in the flight deck continues, with the introduction of touchscreens in the 777X forward displays; a first in the air transport industry.

Popular Science lists 777X among "Best of What's New"

Nov 30, 2015 | Boeing Commercial

Wing size matters - bigger wings generate greater lift, which can improve an airplane's fuel efficiency.

Boeing Completes 777X Firm Configuration

Aug 27, 2015 | Boeing Commercial

Boeing announced today the completion of the firm configuration milestone for the 777-9, the first member of the 777X family to be developed.

| 777-8 | 777-9 | |

|---|---|---|

| List Price | $360.5 million | $388.7 million |

| Market Offerability | May 2013 | May 2013 |

| Program Launch | November 2013 | November 2013 |

| Seats (2-class) | 350-375 | 400-425 |

| Range | 8,700 nmi (16,110 km) | 7,600 nmi (14,075 km) |

| Length | 70 m (229 ft) | 77 m (252 ft) |

| Wingspan Extended | 72 meters | |

| Wingspan On ground | 65 meters | |

| Folding wing-tip | Enables 23 feet (7 meters) more span to maximize fuel efficiency | |

| Interior | Larger windows, wider cabin, new lighting, new architecture | |

| Configuration | Twin-aisle | |

| Engine | GE9X | |

Folding raked wingtip

The Future of Flight Unfolding

Simple design enables compatibility

The 777X’s folding raked wingtip and optimized span deliver greater efficiency, significant

fuel savings and complete airport gate compatibility.

New composite high-span wing

All-new high-efficiency composite wing

Completely optimized wingspan

The 777X's revolutionary design and composite wing make-up allow it to stretch the limits of span

beyond any competing aircraft.

New GE9X engine

The world’s next great engine

The 777X will be powered by the most advanced, fuel-efficient commercial aircraft engine ever built. Designed specifically for the 777X, the all-new GE9X engine features extraordinarily efficient core technology and a composite fan optimized for the 777X

A new passenger experience

Advancing the Passenger-Preferred Interior

The luxurious 777X Cabin

The cabin interior of the 777X is inspired by the 787 Dreamliner and will include larger windows,

a wider cabin, new lighting and enhanced architecture.

Technical Specs

| 777-8 | 777-9 | |

|---|---|---|

| Market Offerability | May 2013 | May 2013 |

| Program Launch | November 2013 | November 2013 |

| Passengers | 350-375 passengers | 400-425 passengers |

| Range | 8,700 nautical miles (16,110 km) | 7,600 nautical miles (14,075 km) |

| Wingspan In-flight | 235 feet 5 inches (71.8 meters) | |

| Wingspan Folded (on ground) | 212 feet 8 inches (64.8 meters) | |

| Folding wing-tip | Enables 23 feet (7 meters) more span to maximize fuel efficiency | |

| Interior | Larger windows, wider cabin, new lighting, new architecture | |

| Configuration | Twin-aisle | |

| Engine | GE9X, supplied by GE Aviation | |

Technical Specs

-

Market Offerability May 2013 Program Launch November 2013 Passengers 350-375 passengers Range 8,700 nm (16,110 km) Wingspan In-flight 235' 5" (71.8 meters) Wingspan Folded 212' 8" (64.8 meters) Configuration Twin-aisle Engine GE9X, supplied by GE -

Market Offerability May 2013 Program Launch November 2013 Passengers 400-425 passengers Range 7,600 nm (14,075 km) Wingspan In-flight 235' 5" (71.8 meters) Wingspan Folded 212' 8" (64.8 meters) Configuration Twin-aisle Engine GE9X, supplied by GE