State of the art 777X Composite Wing Center completes parts

Construction on the 1.3 million-square-foot (121,000-square-meter) building continues, as it will for the next 18 months, with the roll-in of new tools and equipment.

Dec 6, 2016 | Boeing Commercial

Construction on the 1.3 million-square-foot (121,000-square-meter) building continues, as it will for the next 18 months, with the roll-in of new tools and equipment. Preproduction parts for the 777X are underway. Nearly 130 mechanics are testing equipment and the first prototype parts, while another 170 employees have moved into the offices so far.

"It's pretty incredible," said Brett Miller, a 777X tool engineer, noting that real tools and equipment that previously existed only on computer screens and design reviews are coming together.

The building will support fabrication of the 777X wing, the longest wing Boeing has ever built, and turn the Everett site into a center for advanced carbon-fiber technology.

Production of the first 777X is expected to begin next year. Following flight testing and certification programs, the first delivery is scheduled for 2020. The aircraft's GE9X turbofan engines also recently passed two testing milestones in preparation for their delivery to Boeing.

The company has invested more than $1 billion to construct the new facility. In grand opening ceremonies for the building in May, Boeing and community leaders said the company's sizable capital investments in the 777X, along with other Boeing programs and capabilities based in the region, will provide continued jobs and benefits to employees and their communities for years to come.

- Roles

- Subject

- Media

- Event

Boeing Poised To Begin 777X Assembly

Feb 26, 2018 | Aviation Week

Incredibly, it was almost a quarter of a century ago that Boeing program managers described the impending convergence of parts for construction of the first 777 at Everett, Washington, as an “aluminum avalanche.” Fast forward to 2018...

VIDEO: World's Largest 3D Printed Object for 777X

Feb 9, 2018 | Innovations

Boeing partnered with the U.S. Department of Energy’s Oak Ridge National Laboratory (ORNL) to create a tool used to build the folding wing tip for the forthcoming 777X airplane. The wing trim and drill tool is ...

FACEBOOK LIVE: A Behind the Scenes Look at th...

Feb 8, 2018 | Boeing Commercial

Click to Watch the Facebook LIVE

VIDEO: 'Listening' to the new 777X window pan...

Oct 10, 2017 | Boeing Commercial

Click to Watch the Video

State of the art 777X Composite Wing Center completes parts

Dec 6, 2016 | Boeing Commercial

Construction on the 1.3 million-square-foot (121,000-square-meter) building continues, as it will for the next 18 months, with the roll-in of new tools and equipment.

Touchscreens come to 777X flight deck

Jul 1, 2016 | Boeing Commercial

Boeing's innovation in the flight deck continues, with the introduction of touchscreens in the 777X forward displays; a first in the air transport industry.

Popular Science lists 777X among "Best of What's New"

Nov 30, 2015 | Boeing Commercial

Wing size matters - bigger wings generate greater lift, which can improve an airplane's fuel efficiency.

Boeing Completes 777X Firm Configuration

Aug 27, 2015 | Boeing Commercial

Boeing announced today the completion of the firm configuration milestone for the 777-9, the first member of the 777X family to be developed.

| 777-8 | 777-9 | |

|---|---|---|

| List Price | $360.5 million | $388.7 million |

| Market Offerability | May 2013 | May 2013 |

| Program Launch | November 2013 | November 2013 |

| Seats (2-class) | 350-375 | 400-425 |

| Range | 8,700 nmi (16,110 km) | 7,600 nmi (14,075 km) |

| Length | 70 m (229 ft) | 77 m (252 ft) |

| Wingspan Extended | 72 meters | |

| Wingspan On ground | 65 meters | |

| Folding wing-tip | Enables 23 feet (7 meters) more span to maximize fuel efficiency | |

| Interior | Larger windows, wider cabin, new lighting, new architecture | |

| Configuration | Twin-aisle | |

| Engine | GE9X | |

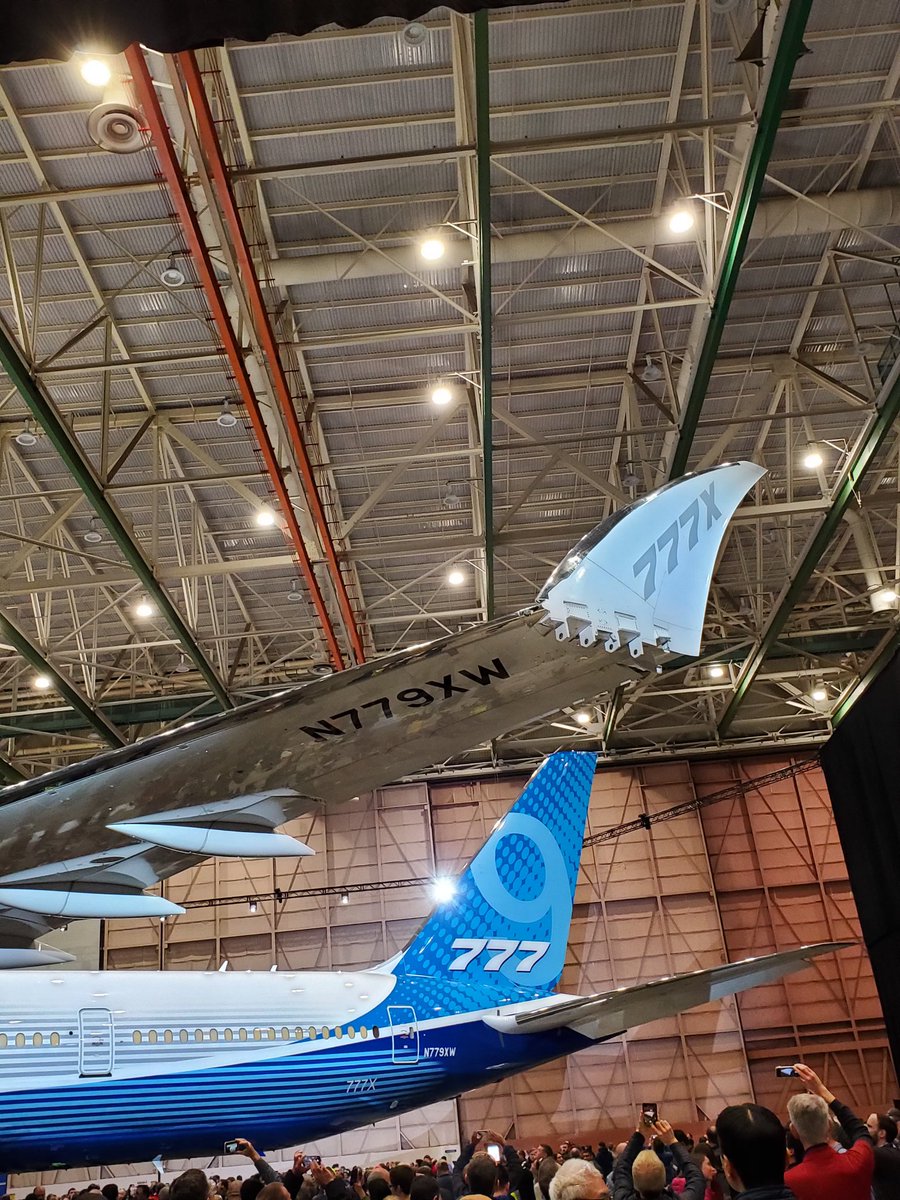

Folding raked wingtip

The Future of Flight Unfolding

Simple design enables compatibility

The 777X’s folding raked wingtip and optimized span deliver greater efficiency, significant

fuel savings and complete airport gate compatibility.

New composite high-span wing

All-new high-efficiency composite wing

Completely optimized wingspan

The 777X's revolutionary design and composite wing make-up allow it to stretch the limits of span

beyond any competing aircraft.

New GE9X engine

The world’s next great engine

The 777X will be powered by the most advanced, fuel-efficient commercial aircraft engine ever built. Designed specifically for the 777X, the all-new GE9X engine features extraordinarily efficient core technology and a composite fan optimized for the 777X

A new passenger experience

Advancing the Passenger-Preferred Interior

The luxurious 777X Cabin

The cabin interior of the 777X is inspired by the 787 Dreamliner and will include larger windows,

a wider cabin, new lighting and enhanced architecture.

Technical Specs

| 777-8 | 777-9 | |

|---|---|---|

| Market Offerability | May 2013 | May 2013 |

| Program Launch | November 2013 | November 2013 |

| Passengers | 350-375 passengers | 400-425 passengers |

| Range | 8,700 nautical miles (16,110 km) | 7,600 nautical miles (14,075 km) |

| Wingspan In-flight | 235 feet 5 inches (71.8 meters) | |

| Wingspan Folded (on ground) | 212 feet 8 inches (64.8 meters) | |

| Folding wing-tip | Enables 23 feet (7 meters) more span to maximize fuel efficiency | |

| Interior | Larger windows, wider cabin, new lighting, new architecture | |

| Configuration | Twin-aisle | |

| Engine | GE9X, supplied by GE Aviation | |

Technical Specs

-

Market Offerability May 2013 Program Launch November 2013 Passengers 350-375 passengers Range 8,700 nm (16,110 km) Wingspan In-flight 235' 5" (71.8 meters) Wingspan Folded 212' 8" (64.8 meters) Configuration Twin-aisle Engine GE9X, supplied by GE -

Market Offerability May 2013 Program Launch November 2013 Passengers 400-425 passengers Range 7,600 nm (14,075 km) Wingspan In-flight 235' 5" (71.8 meters) Wingspan Folded 212' 8" (64.8 meters) Configuration Twin-aisle Engine GE9X, supplied by GE